Snow buddy

Introduction

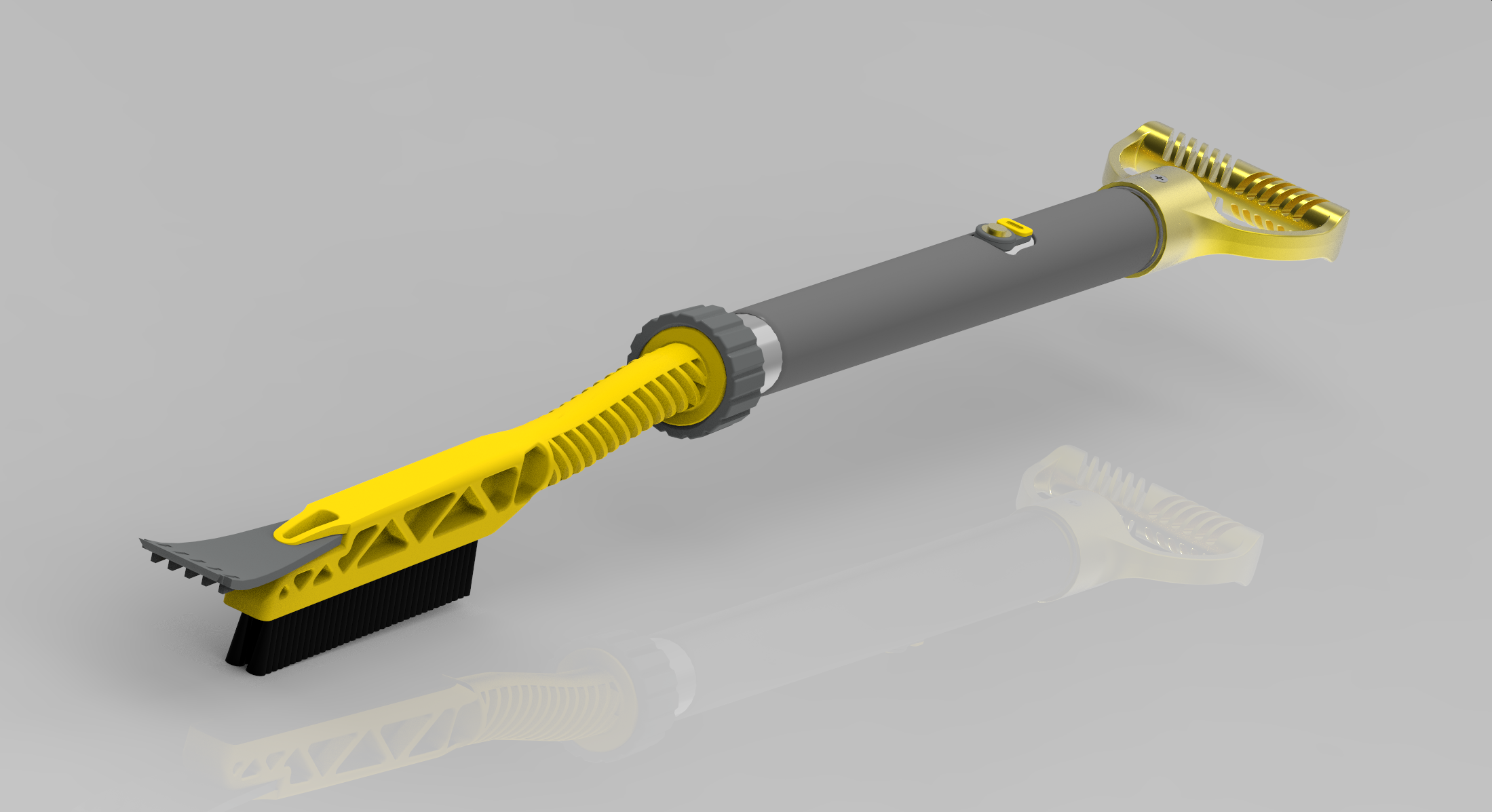

Every car owner in snowy regions must clear snow from their car during the winter. Freezing temperatures typically make this a very unpleasant experience, but the chore can be greatly improved by using our heated combination ice scraper, snow brush, and snow shovel. Introducing, the SnowBuddy!

Concept Development

The initial design concept that the team landed on was a multi purpose ice scraper and shovel that uses an internal heating system. This product had a few key aspects that would be the primary focus for development. The first would be an easy and strong modular design for swapping between the shovel and ice scraper attachments. The second would be a robust heating system that provides both the required heat output and the battery life our customers will expect from a quality product. Additionally ergonomics would be essential due to the forces required for both shoveling and ice scraping.

initial Prototype

The initial design focused on creating a user centric product that fit the ergonomic requirements of something that is going to be used in a variety of harsh conditions.

SImulation

Thermal simulation was used to test the overall performance requirements and proof of concept. The team was able to achieve intended temperature levels in the most intense wind and low temperature conditions. This also informed the power requirements from the battery system and proved that the product could achieve hours of battery life under maximum power requirements.

DVT

These renders show the DVT and are rendered in clear in order to better show the internal geometry. The design relies on an aluminum extrusion for the outer casing with an injection molded internal clamshell that holds the battery and electronics. The enclosure has an internal rail system that all the internal elements slide onto in order to ensure all the components are oriented correctly.

PVT

The PVT refined the overall concept with a strong focus on ergonomics and manufacturability. This stage involved creating technical drawings for each component and a full BOM for the entire assembly. For the injection molded components the drawings included parting lines and surface finish instructions. The entire unit is weather sealed with o-rings and features an optimized quick release system for fast swapping between the two attachments. Manufacturing and assembly was a key concern during this phase and the finished design reflects these considerations.

Final Renders

BOM and Drawings: